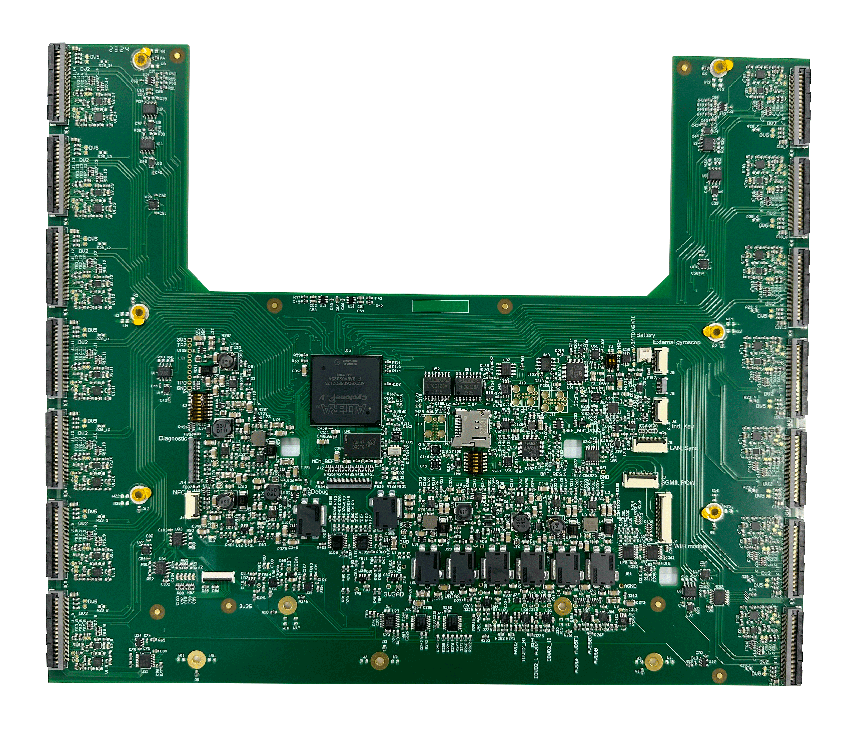

In today’s medical technology, reliability and miniaturization are everything. Devices like pacemakers, imaging probes, and wearable sensors demand electronics that are light, durable, and compact — yet powerful enough to perform safely in critical environments.

This is where rigid flex pcb for medical devices excels. Its hybrid design of rigid and flexible layers creates circuits that fit tight spaces while maintaining electrical performance and structural strength.

Why Medical Devices Prefer Rigid-Flex Designs

Medical engineers are constantly challenged to make devices smaller and more reliable. Rigid-flex PCBs are ideal because they replace bulky wiring harnesses and connectors with thin, integrated circuits.

By combining rigid sections (for component mounting) with flexible interconnects, these boards allow 3D packaging, reduce weight, and eliminate potential connection failures.

Common medical applications include:

- Implantable devices like pacemakers or neurostimulators

- Diagnostic imaging tools such as ultrasound and MRI probes

- Drug delivery systems and surgical instruments

- Wearables and catheter-based sensors

In all these examples, space is limited, and reliability is vital. Rigid-flex PCBs provide both — they are compact, vibration-resistant, and engineered to perform through thousands of mechanical cycles.

Key Design and Manufacturing Rules

When building rigid-flex circuits for healthcare, careful design makes the difference between success and failure.

1. Bend radius and neutral plane

The flexible layers should bend around a neutral axis to prevent copper fatigue. Keep the copper traces centered and avoid bending over vias or components. Static and dynamic flex zones need different radii — for dynamic bending, plan at least 100 times the flex thickness.

2. Layer stack-up and materials

Typical constructions use polyimide (PI) for flexible layers and FR-4 for rigid areas. Adhesive or adhesive-less laminates may be used depending on temperature and reliability needs. Coverlay films protect copper from moisture and chemicals, which is important in sterilization environments.

3. Controlled impedance and trace routing

For imaging and diagnostic tools that transmit high-frequency signals, impedance control is essential. Designers should define trace widths, spacing, and dielectric thickness accurately to maintain signal integrity. Cross-talk and EMI can be minimized with solid reference planes and proper spacing.

4. Assembly and manufacturability

Components should be placed in rigid areas to avoid stress during reflow. During SMT, flexible sections require mechanical support or stiffeners. Thermal profiles must match the polyimide’s tolerance to prevent delamination.

Compliance and Quality Standards for Healthcare Electronics

Medical electronics are held to higher standards than commercial products. Every board must be traceable, safe, and stable under sterilization or cleaning cycles.

1. Certifications and process control

Manufacturers should operate under ISO 13485 and ISO 9001 quality systems, with documented process validation and lot tracking. UL certification and IPC-A-610 Class 3 workmanship are common requirements for medical customers.

2. Material safety and biocompatibility

All materials — copper, adhesives, coverlays, and finishes — must comply with RoHS and REACH regulations. They should also withstand contact with sterilization gases, chemicals, or body fluids, depending on device type.

3. Reliability testing

Rigid-flex boards for medical use often undergo flex-life testing, dielectric withstand, impedance verification, and accelerated aging. This ensures consistent performance through sterilization, vibration, and long-term use.

In short, compliance and documentation are not optional — they are central to patient safety and regulatory approval.

Real-World Medical Applications

Rigid-flex technology supports a wide range of life-critical devices:

- Implantables: Pacemakers, cochlear implants, and neurostimulators rely on tiny, stable circuits that endure years inside the human body.

- Imaging and diagnostics: Ultrasound probes, CT sensors, and handheld scanners need lightweight flex interconnects for ergonomic, high-channel-count systems.

- Drug delivery and surgical tools: Compact pump controls or disposable surgical devices benefit from simple assembly and fewer interconnects.

- Wearables and catheters: These require ultra-thin, lightweight, and repeatedly bendable circuits that can survive constant motion and sterilization.

By combining flexibility and reliability, rigid-flex PCBs enable modern healthcare electronics to be smaller, smarter, and more durable.

From Prototype to Production: Speed and Supplier Capabilities

Medical programs move fast — engineers often need prototypes in days, not weeks. That’s why choosing a capable manufacturer matters.

What to look for in a partner:

- Proven experience in medical electronics

- Rigid-flex multilayer and fine-line capabilities

- Controlled impedance and testing expertise

- ISO 13485, UL, and RoHS/REACH compliance

- Responsive engineering and short lead times

A strong PCB partner will shorten development cycles, minimize risk, and ensure consistent quality from prototype to mass production.

Why Consider FastTurn PCB

When choosing a manufacturing partner, reliability and turnaround speed go hand in hand. FastTurn PCB offers one-stop PCB fabrication and assembly services, including rigid-flex, flex, and multilayer designs.

The company provides full turnkey solutions — from Gerber review, material selection, and fabrication to component sourcing, SMT/THT assembly, and functional testing. Its engineering team works closely with customers to identify design risks early and deliver manufacturable solutions quickly.

FastTurn’s facilities are certified to ISO 13485, ISO 9001, and UL standards, and comply with RoHS and REACH directives. Whether you need a single prototype or volume production, their quick-turn service ensures your medical electronics move from concept to clinical use without delay.

Frequently Asked Questions

1. What’s the main difference between rigid-flex and regular PCBs?

Rigid-flex PCBs combine rigid and flexible layers, enabling 3D routing and reducing the need for connectors. They cost slightly more but improve reliability and assembly efficiency, especially in compact devices.

2. How do I estimate the correct bend radius?

As a general rule, use a minimum bend radius of 10× the flex thickness for static bends and 100× for dynamic bends. Thinner copper and proper coverlay openings help prevent cracking.

Conclusion

Rigid-flex circuits enable the next generation of medical devices — smaller, more reliable, and capable of withstanding demanding environments.

By following good design rules, ensuring compliance, and working with an experienced manufacturer like FastTurn PCB, medical device developers can accelerate prototyping and bring innovative healthcare solutions to market more quickly and safely.