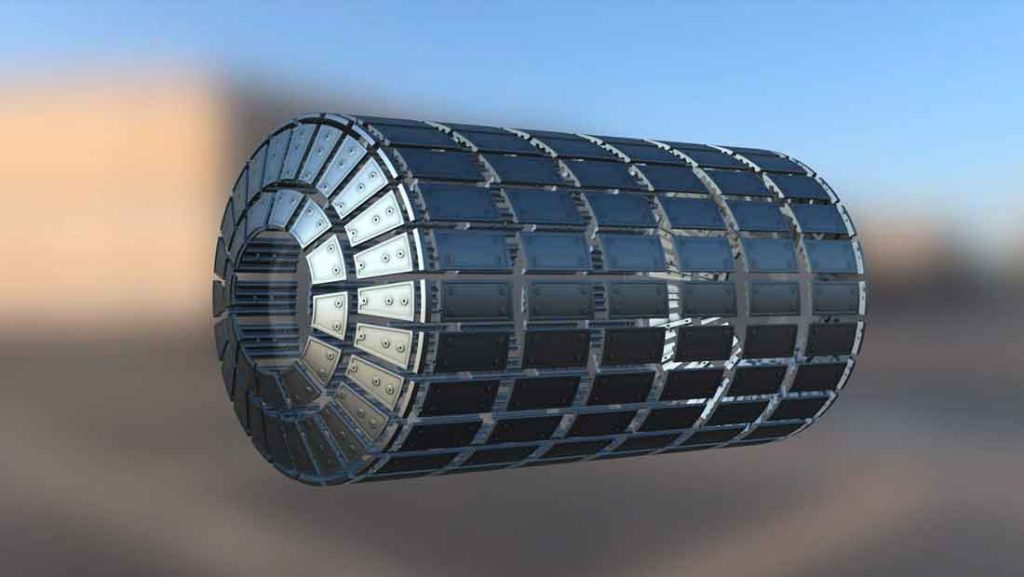

The selection of the right alloy for mill liners is crucial for the optimisation of their performance and durability. This involves a comprehensive understanding of the operational environment and the specific material properties required to withstand the stresses encountered in milling processes. Companies that focus on expert alloy selection for mill liners ensure prolonged service life and reduced operational costs.

The Importance of Alloy Selection

Alloy selection plays an integral role in determining the wear resistance and toughness of mill liners. By carefully choosing the materials, operators can enhance the operational efficiency and longevity of their grinding mills. The right alloy can withstand the impact and abrasive forces present in milling, reducing the frequency of maintenance and replacements.

Factors Influencing Alloy Choices

Several factors influence the choice of alloy for mill liners. These include the type of ore being processed, the mill design, operational speed, and the desired lifespan of the liner. By analysing these factors, experts can recommend the most suitable alloy that will provide optimal performance.

Common Alloy Types Used in Mill Liners

Various types of alloys are used in mill liners, each offering distinct benefits. Common alloys include high-chrome alloys known for their superior wear resistance, and manganese steels that provide excellent toughness. The selection between these, and other specialised materials, depends largely on the specific milling conditions.

High Chrome Alloys

High chrome alloys are favoured in environments where abrasion resistance is critical. These materials offer enhanced durability and a longer lifespan, making them ideal for use in aggressive milling conditions.

Manganese Steels

Manganese steels are selected for their exceptional toughness and ability to work harden with impact. This makes them particularly suitable for applications where high impact is a concern, ensuring the liners remain intact under tough conditions.

The Role of Customisation in Alloy Selection

Customisation in alloy selection can significantly improve the performance of mill liners. By tailoring the alloy composition to meet specific operational requirements, manufacturers can optimise the balance between toughness and wear resistance, preventing premature failures.

Advancements in Alloy Technology

Recent advancements in material science have led to the development of new alloys that offer improved performance characteristics. These innovations allow for the creation of liners that are lighter, longer-lasting, and capable of enduring more extreme conditions than ever before.

Performance Testing and Quality Control

Before choosing an alloy for mill liners, comprehensive performance testing and quality control measures must be undertaken. This ensures that the selected material meets the requisite standards and can perform effectively in real-world conditions.

Understanding the Cost-Benefit Equation

While the initial cost of high-performance alloys may be higher, the overall cost-benefit analysis often reveals that the longevity and reduced maintenance requirements make them a more cost-effective choice in the long run.

Real-World Applications

The right alloy selection not only improves liner performance but also enhances the overall efficiency of the milling process. Industries worldwide depend on expert alloy selection for mill liners to ensure optimal operations and economic viability.

Conclusion

The process of selecting the correct alloy for mill liners is a complex yet critical undertaking. Through a careful evaluation of operational requirements and an understanding of material properties, significant advancements in mill liner performance can be achieved. The future of milling depends on continued innovations and informed selections in this vital area.