In the world of modern manufacturing, achieving precision, durability, and functionality in components is essential. Two critical processes that support these goals are CNC machining surface finishing and insert molding applications. While CNC machining ensures accurate cutting and shaping of materials, surface finishing techniques refine the product’s quality and appearance. On the other hand, insert molding offers an innovative way to combine different materials into a single, functional part. Together, these methods play a significant role across industries such as automotive, aerospace, electronics, and medical devices.

This article explores both CNC machining surface finishing techniques and insert molding applications in detail, highlighting their importance, benefits, and real-world use cases.

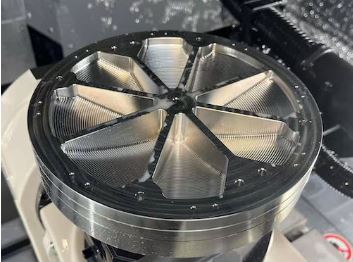

Understanding CNC Machining

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where computer-controlled machines cut away material from a workpiece to create complex parts. It is widely used for producing high-precision components in metals, plastics, and composites. The process includes milling, turning, drilling, and grinding, which provide exceptional accuracy. However, once machining is complete, the part often requires surface finishing to improve aesthetics, functionality, and durability.

Importance of CNC Machining Surface Finishing

Surface finishing in CNC machining is not just about looks; it also improves mechanical performance, corrosion resistance, and wear resistance. A well-finished part has better functionality and is more reliable in demanding applications. CNC machining surface finishing enhances dimensional accuracy, reduces friction, and improves bonding during assembly.

Common CNC Machining Surface Finishing Techniques

- Anodizing

Anodizing is commonly used for aluminum parts. It provides a protective oxide layer that improves corrosion resistance while offering color customization. - Powder Coating

Powder coating applies a durable, high-quality finish suitable for parts exposed to harsh conditions. It provides better adhesion and longevity compared to traditional paints. - Polishing

Polishing improves the smoothness and shine of the surface, often used for parts requiring an aesthetic finish or reduced friction. - Bead Blasting

Bead blasting creates a uniform matte finish by using fine glass beads, ideal for parts where a consistent appearance is essential. - Electroplating

Electroplating adds a thin layer of metal such as gold, nickel, or chrome to improve conductivity, wear resistance, and appearance. - Passivation

Common for stainless steel, passivation removes impurities and enhances corrosion resistance without altering dimensions.

Benefits of CNC Machining Surface Finishing

- Increases durability of the product

- Improves corrosion and wear resistance

- Enhances appearance and branding opportunities

- Prepares surfaces for secondary processes such as painting or bonding

- Provides smoother operation in mechanical assemblies

Introduction to Insert Molding

Insert molding is a manufacturing process where metal or plastic inserts are placed into a mold before injecting molten material around them. This method produces a single, integrated component with multiple materials. Unlike traditional assembly, which requires welding, fastening, or adhesives, insert molding creates a strong bond between different materials during the molding process.

Insert Molding Applications Across Industries

Insert molding is highly versatile and used in numerous industries due to its ability to reduce assembly time, minimize costs, and improve part performance.

Automotive Industry

In the automotive sector, insert molding applications include producing gear components, dashboard assemblies, and electronic connectors. It helps improve strength, reduce part weight, and integrate metal reinforcements into plastic components.

Electronics Industry

Insert molding is commonly used for connectors, switches, and housings in electronic devices. By combining metal inserts with plastic casings, manufacturers achieve durability, miniaturization, and better electrical conductivity.

Medical Devices

In the medical industry, insert molding produces surgical instruments, handles, and housings that combine metal precision with plastic ergonomics. The process ensures biocompatibility and easy sterilization.

Aerospace Applications

The aerospace industry relies on insert molding for producing lightweight yet durable components such as brackets, housings, and structural reinforcements. These parts must withstand extreme conditions, making insert molding ideal for enhancing performance.

Consumer Products

Everyday products such as kitchen tools, handles, and mobile accessories often use insert molding. It improves grip, comfort, and strength while maintaining an attractive appearance.

Advantages of Insert Molding

- Reduces assembly costs by eliminating secondary fastening

- Provides strong bonding between dissimilar materials

- Improves part consistency and structural integrity

- Allows miniaturization of components in electronics and medical devices

- Enhances durability and resistance to vibration and wear

Comparing CNC Machining Surface Finishing and Insert Molding Applications

While CNC machining surface finishing focuses on improving the properties and aesthetics of machined parts, insert molding applications revolve around combining materials into a single integrated component.

- CNC Machining Surface Finishing enhances the performance and appearance of metal and plastic parts after machining.

- Insert Molding Applications provide design flexibility and reduce assembly costs by integrating different materials in one process.

Together, these methods often complement each other. For example, a CNC-machined insert may undergo surface finishing for corrosion resistance before being used in an insert molding process. This ensures the final component offers both strength and longevity.

Future Trends in Manufacturing

As industries move towards automation, lightweight materials, and sustainable practices, both CNC machining surface finishing and insert molding applications will evolve. Advanced coatings, eco-friendly finishes, and new composite materials will expand possibilities in manufacturing. Additionally, the integration of additive manufacturing with these processes will open new opportunities for design complexity and cost reduction.

Conclusion

CNC machining surface finishing and insert molding applications represent two pillars of modern manufacturing. While CNC machining ensures precision and refinement through advanced finishing techniques, insert molding applications the integration of multiple materials into a single, reliable component. Together, they enhance efficiency, durability, and functionality across industries such as automotive, aerospace, electronics, medical, and consumer products.